We help transform your ideas into real, market ready products. Our approach to product design balances aesthetics and functionality, ensuring that your product not only performs flawlessly but also stands out visually in a competitive market.

At SFACTO, we specialize in delivering end-to-end solar manufacturing engineering and automation solutions. From initial concept layouts to full-scale production line integration, we design, engineer, and implement manufacturing systems that maximize efficiency, precision, and sustainability.

Our expertise spans across cell production, module assembly, material handling, and automation systems, ensuring every stage of your solar manufacturing process is optimized for throughput, quality, and long-term scalability.

Whether establishing a new gigafactory or upgrading existing facilities, we provide seamless coordination between digital design, simulation, tooling, and on-site commissioning — enabling future-ready solar production lines that accelerate your clean energy goals.

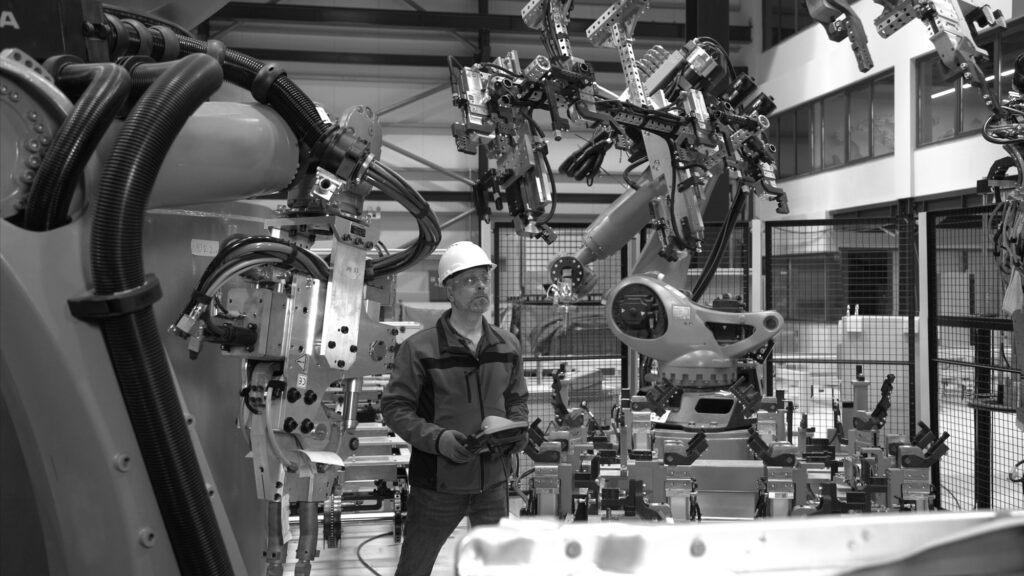

At SFACTO, we design and implement advanced automation lines for EV battery production — from electrode preparation to final pack assembly.

Our solutions combine robotics, precision tooling, and digital engineering to deliver safe, scalable, and high-quality battery manufacturing systems. With expertise in material handling, sealing, testing, and traceability, we help OEMs and Tier-1 suppliers accelerate production while ensuring compliance with global safety and performance standards. Whether launching a new platform or upgrading existing facilities, we provide seamless coordination between digital design, simulation, tooling, and on-site commissioning — delivering future-ready production lines on time and with confidence.

At SFACTO, We empower fuel cell manufacturers with end-to-end automation and engineering solutions — from electrode fabrication to stack assembly and final testing. Our expertise spans material handling, precision joining, sealing, testing, and traceability, enabling OEMs to scale fuel cell production with higher yield, lower costs, and strict compliance with global standards.

Whether setting up a new gigafactory for hydrogen mobility or optimizing existing production lines for stationary energy systems, we deliver digital design, simulation, and turnkey automation lines that accelerate the clean energy transition.

Choose SFACTO for a partnership where innovation meets customization

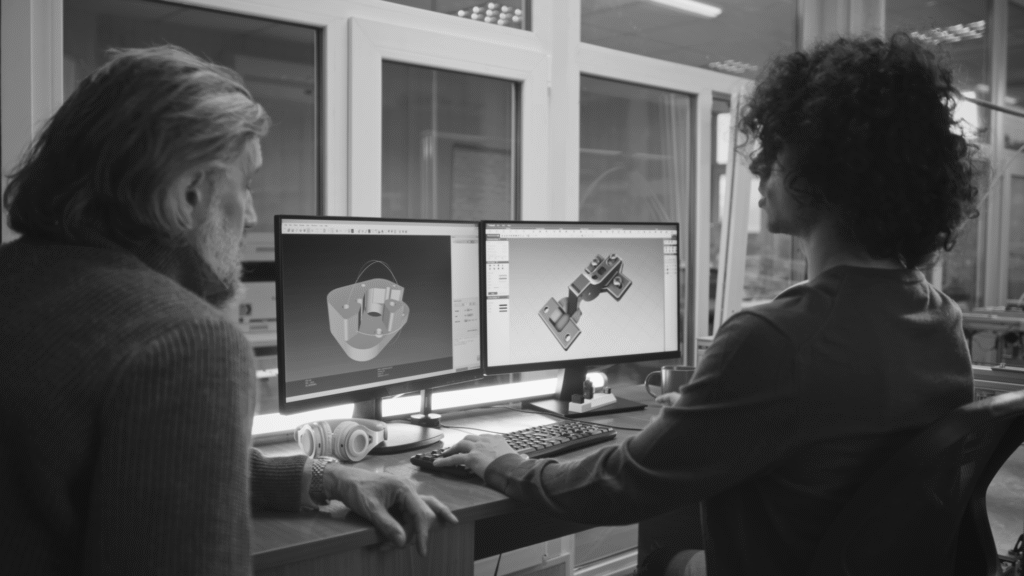

Our highly qualified experts collaborate with customers throughout the production lifecycle, providing professional, technical, and cost-efficient solutions alongside tailored resolutions.

The design and simulation of automation processes and equipment are conducted in close collaboration with our customers. This approach enables us to effectively address individual requirements and ensure maximum system availability throughout the production phase.

From the manufacturing of equipment and its safe shipment, through pre-assembly and commissioning at our facilities, to onsite installation and final prove-outs. We meticulously manage every phase to ensure seamless progress, quality, and efficiency at every step.

Our comprehensive aftermarket solutions, featuring digital monitoring, system upgrades, performance optimization, and rapid technical support, ensure long-term reliability and sustained operational excellence beyond project handover.

We value punctuality and reliability, ensuring every project is delivered on time—without delays or excuses

Respecting your budget, staying transparent, and open to negotiation at every stage— to find the right fit together.

We go the extra mile to deliver beyond expectations and We believe our customers’ success is our success.